Everything You Need to Know About Electric Fencing

Introduction

Building a good electric fence is like anything else, you get out what you put in. If you use the proper equipment and maintain the fence the result will be a permanent structure just like the barb wire you use to use. The advantage of using ‘electric’ or ‘high tensile’ fences is on average they cost less than a barb wire fence, since less materials are required (ie posts, staples and wire) and they take less time to install. The electric fence option is also more versatile; you can take it down quickly and re-install somewhere else. This is particularly useful during times of drought when there are pasture shortages and producers are looking for additional grazing options.

Electric fences are mental barriers not physical barriers for all classes of cattle and grazing situations. When livestock are trained properly and the fence is working the way it was designed to (ie with the proper voltage on the fence), cattle will touch the fence once and than leave it alone. This includes all seasons of grazing or pasture confinement such as spring, summer, fall and winter.

Equipment and Installation Recommendations and Tips

Fencer/Energizer

All equipment should be purchased from a reputable company, thus ensuring good materials that will be backed by your supplier. When purchasing the energizer you should think ‘bigger is better.’ Meaning, purchase a fencer that is a little bigger than your requirements. This will allow for ensuring enough voltage is flowing through the wire to deal with brush and wet grass taking some of the power and for future expansions. A basic rule of thumb is you need no less than 2000 volts in the summer and 4000 volts in the winter due to thicker hair coats on the livestock and you usually do not get a proper ground because of snow.

Tips

- Install fencer where rodents can not chew on the wires (preferably in a building)

- Install a lightening diverter

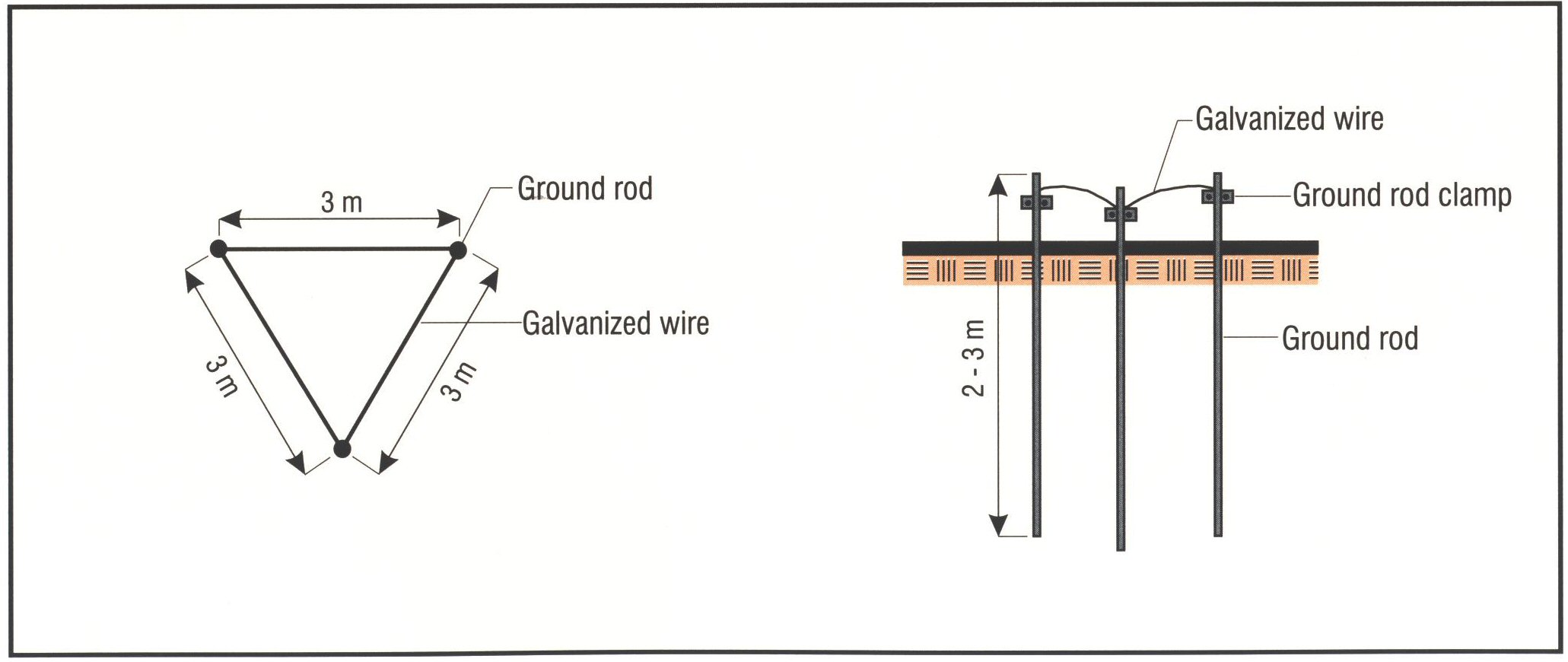

Ground Rods

The grounding system is the most important part of the fence. Ensure you have installed your ground rods properly. You will need a minimum of 3, 6-8 foot long, rods placed at least 2 meters away from the energizer and 3 meters a part from each other. The rods and clamps are connected back to the energizer using galvanized wire.

Once the fence is installed you should check to see if the fence is properly grounded. This is done by ‘grounding’ out the fence with a metal bar and than checking the ground rods with a volt meter. If the reading on the volt meter is higher than 200 volts you need more ground rods. There should be no volt reading on the meter with a properly grounded fence.

Tips

- Use galvanized materials – they do not rust.

Wire

Tips

- Use 12½ gauge galvanized high tensile wire.

- Tie wire properly.

- For a two wire fence the first wire should be 22 inches from the ground and the top wire 40 inches.

- The top and bottom wires should be connected together at least every 1/2 mile.

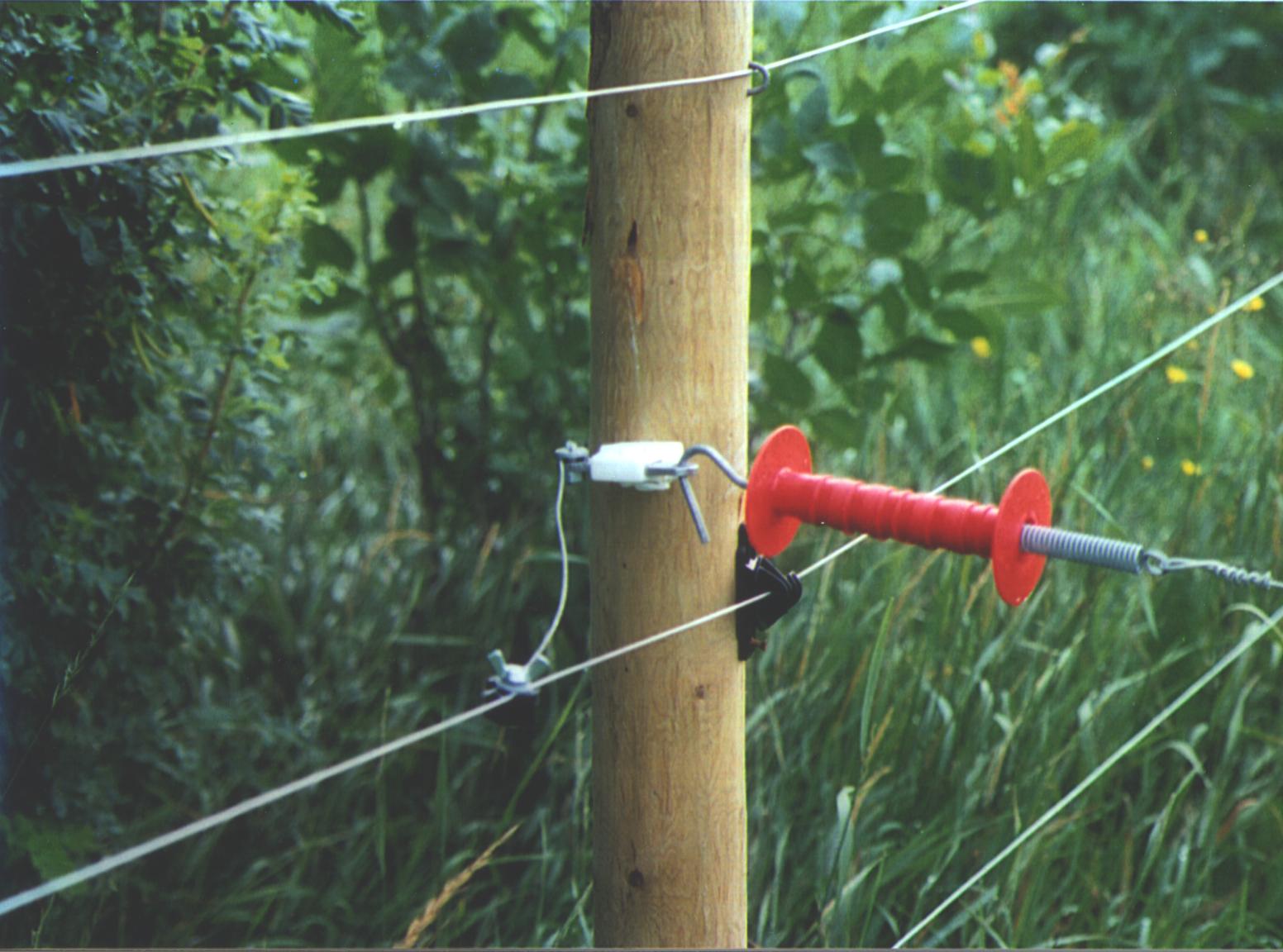

Insulators

Tips

- Buy high quality insulators - they require a nail at top and bottom/insulators requiring a single nail will draw power from the fence.

- Many different manufacturers provide a multi year warranty on insulators and will replace broken ones at no cost to you.

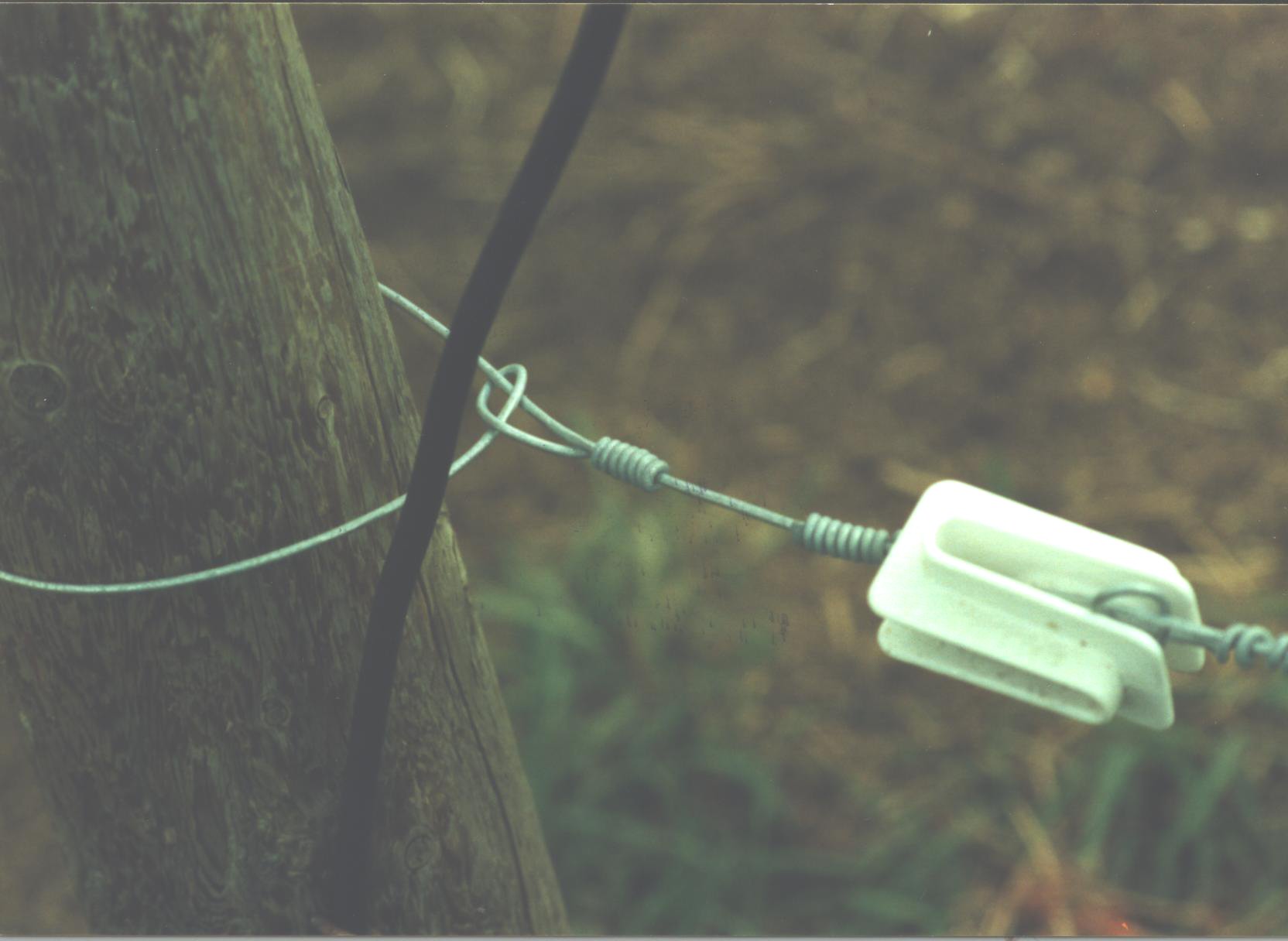

Corner Strainers

Tips

- Tie corners properly.

- Porcelain or plastic strainers are acceptable.

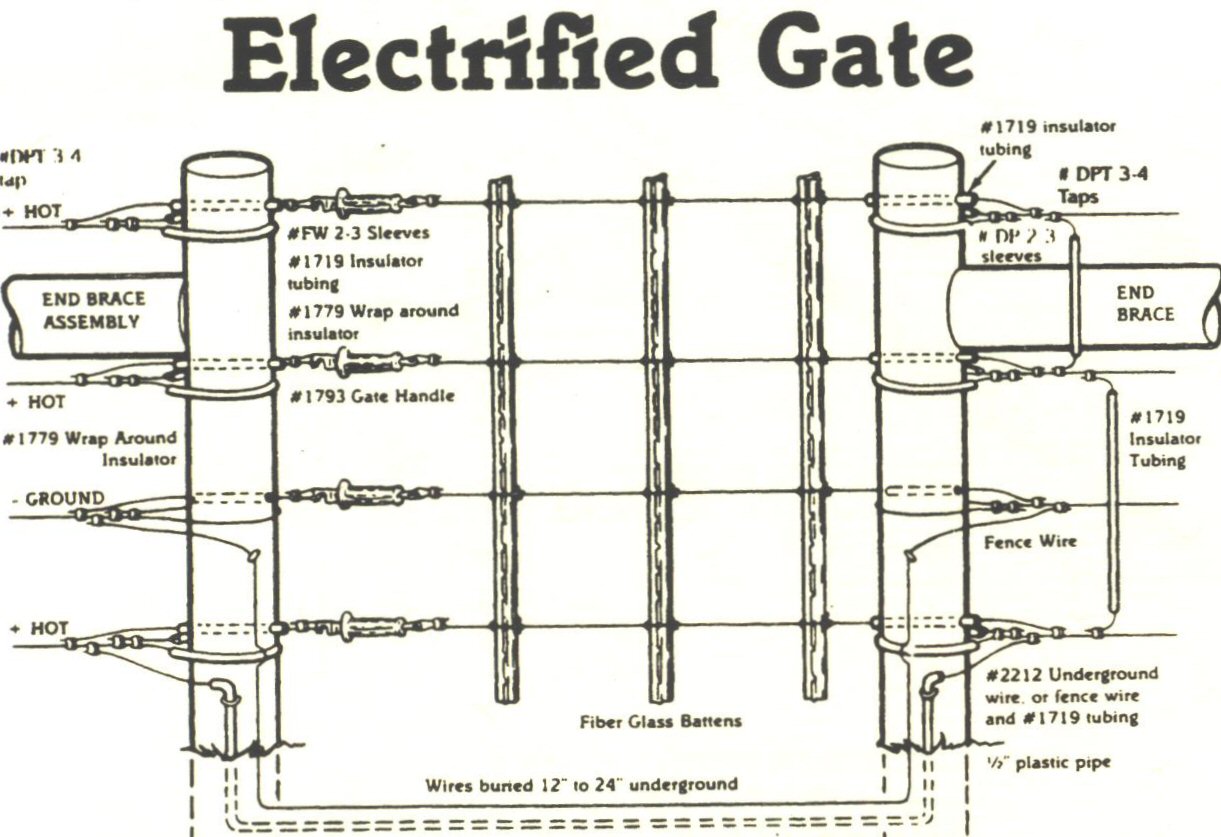

Gates

Tips

- Use a good quality gate kit.

- Underground coated wire is required to transfer power from one side of the gate to another.

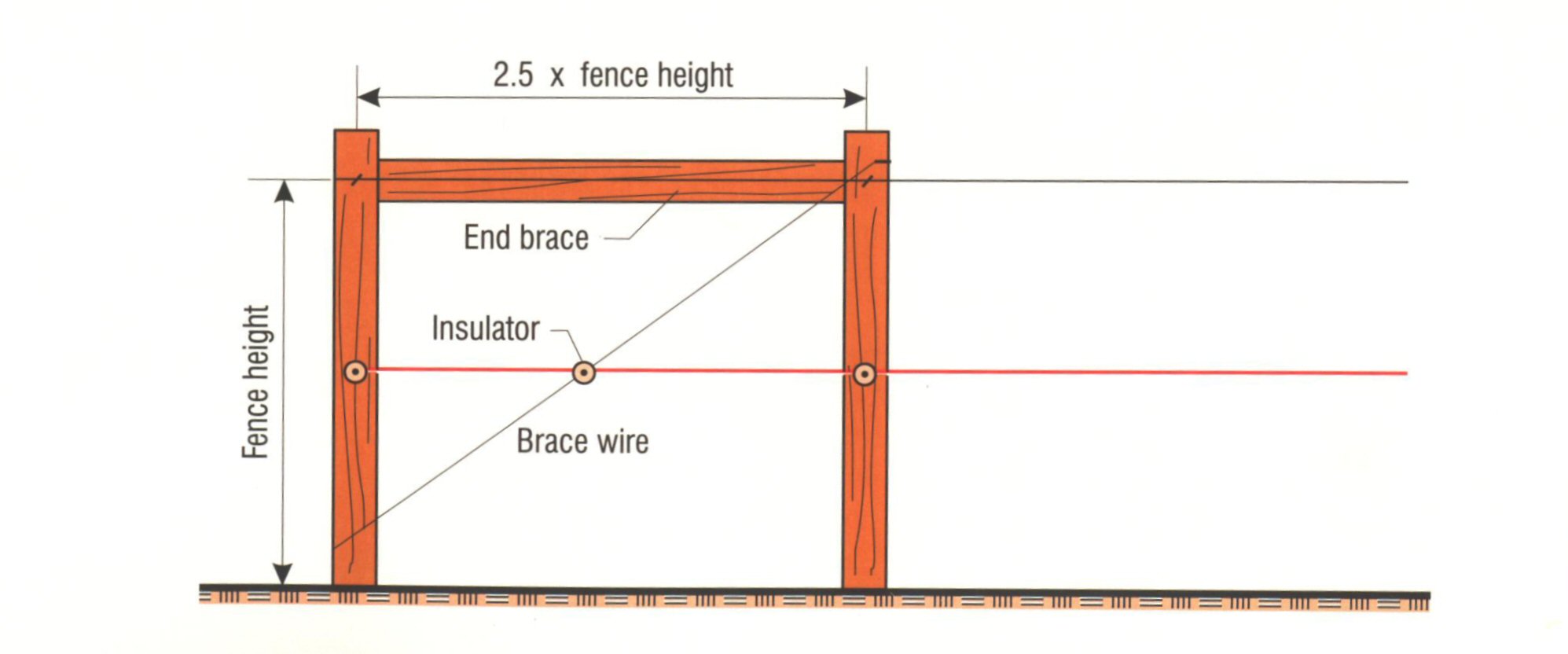

Braces

Braces are the backbone of any good fence.

Tips

- For a one wire paddock division a lighter brace can be used.

- Ensure the horizontal brace is 2.5 times the height of the vertical brace post.

- There are many options to build braces; most critical is to have corner posts (4 to 5") at least at 3.5 feet in the ground. In addition the horizontal brace and straining wire have to be installed correctly.

Posts

Tips

- Post spacing can be up to 60-75 feet with high tensile wire on level ground.

- On hilly ground spacing should not exceed 30-40 feet.

Training Livestock to Respect an Electric Fence

When training livestock to respect an electric fence it is a good idea to use a smaller pasture, approximately three to four acres in size, with a 3 to 4 electrified wire fence. The goal is to shock the animals once and to do this you may need to attract the animals to the wire by tying tinfoil or ribbon to the wire. Cattle are usually quick learners, when shocked once with a 5000-volt fence, they rarely touch it again. After about three to four days all animals should know to avoid the fence. Another way to train livestock to electric fence is to use electrified corrals during the winter feeding period.

Fence Maintenance

One of the most useful tools will be a volt meter or a fault finder. This will help you ensure the proper voltage is being delivered on a regular basis and if you have a fault finder it will speed up the repair process by indicating the direction of the problem.

Every spring it is important to walk the fence line to ensure the insulators are still in place and then wire is tight. As well you can check for debris such as fallen trees which will decrease the power running through the wire. In the winter, if the energizer is not in use, it should be stored in a clean, dry place. If you are using a solar powered electric fence you will want to charge the battery prior to storing it for the winter.

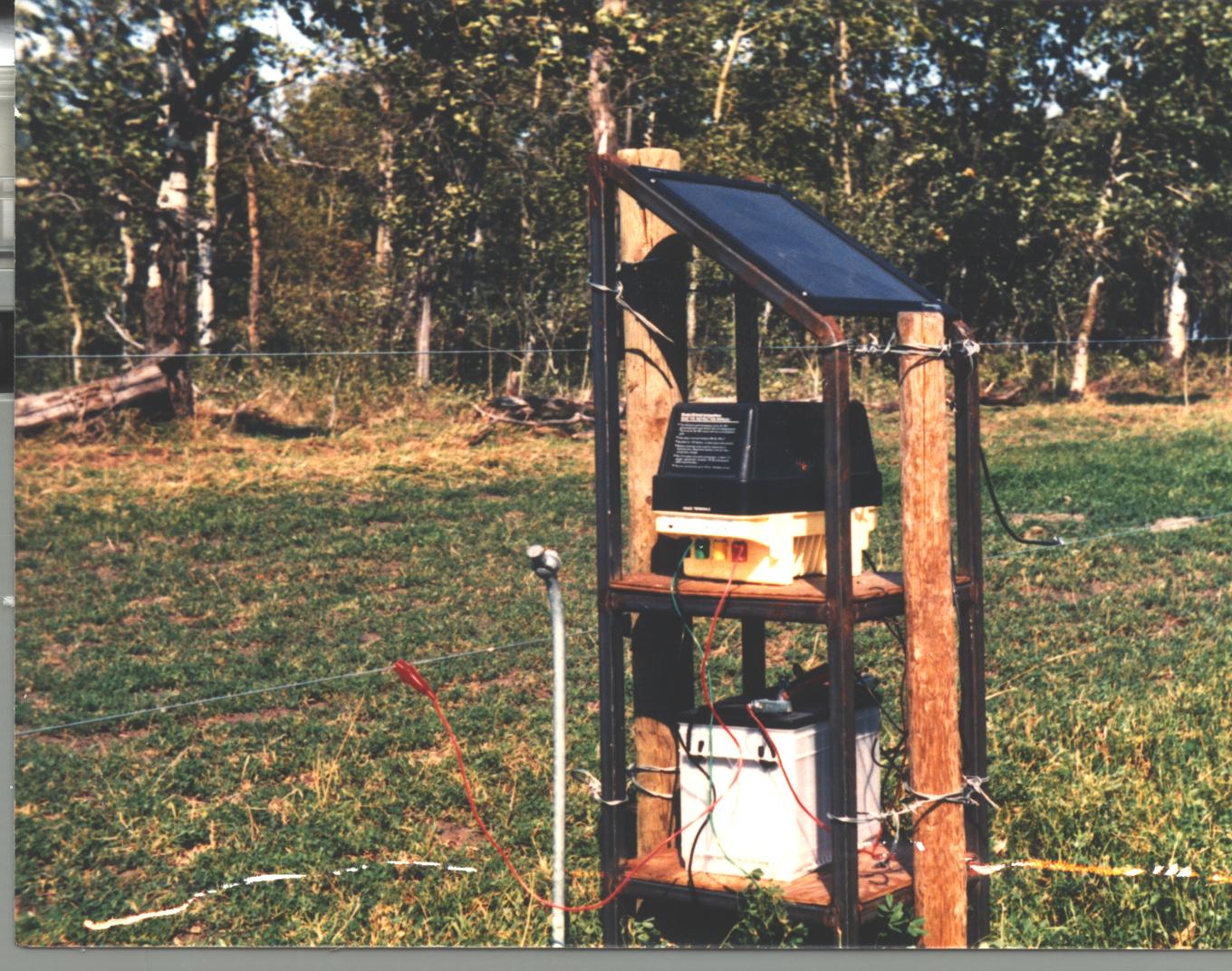

Solar Option

When trying to graze livestock in remote areas, where power is not available solar panels are an option. If you are already using solar water pumping system in a remote area or elsewhere you can hook your energizer up to the existing structure.

Ensure the solar panel is installed properly and facing the sun a high noon. If you place a pencil vertically on the panel at this time of the day there should be no shadow. With this done the solar panel will charge your battery which in turn powers the fence.

Temporary Fencing

Electrified, high tensile wire can be used as an economical, easily install and portal fencing option. his option provides producers with flexibility in rotational grazing systems to divide up paddocks and feed options during periods of drought. Equipment recommended for this type of fencing includes a reel with wire (temporary wore should have at least 6 wires in the tape to carry enough power) and step-in posts.

Dont's of Electric Fencing

- Do not power barb wire.

- Do not use barb wire on gates.

- Do not use your gate wire to transfer power from one side of the brace to the other.

- Do not leave your fence tight over winter; the wire will contract and pull your braces out of line.

- Do not overtighten your wire when installing - just take out the slack.

- Do not turn cattle out into a strange pasture or with cattle that have not been trained to electric fence. It is not a physical barrier and they will run through it.

- Do not run electric wire in conjunction with barb wire.

- Do not use copper wire to connect ground rods to fencer because they corrode.

- Do not tighten high tensile wire if it has been kinked. It will break. Tie proper knots to reconnect.

- Do not use low quality/power robbing supplies - you WILL replace it ALL over time and will not be HAPPY.

Troubleshooting

The most common problem with electric fence is low voltage. This could be due to one or more of the following problems.

- Vegetation/trees on the wire.

Solution: Ensure fence is free from debris - Missing and/or poor quality insulator

Solution: Check insulators and replace missing and/or poor quality - Inadequate grounding

Solution: Add more ground rods or replace corroded ground rods - Low battery in solar system

Solution: Charge or replace battery or replace solar panel with a larger one - Too small of a fencer/energizer

Solution: Buy a larger fence

References:

Fencing with Electricity. 1995. Alberta Agriculture, Food and Rural Development. High Tensile Fence Systems. Dare Products Inc.

Compiled by

Larry Fischer

Livestock Technician, Central Region

Manitoba Agriculture, Food and Rural Initiatives

Melinda German

Cow/Calf Specialist

Manitoba Agriculture, Food and Rural Initiatives