The "Green Gold" Program

Deciding when to harvest quality forage in Manitoba is often a guessing game. Traditionally, the optimum time to harvest the first cut has been determined on the basis of late bud, or the appearance of the first bloom. However, bud or bloom development may be delayed by climatic condition and is not always the best guideline.

To address this problem, the Manitoba Green Gold program was established to determine the ideal date to make that first cut.

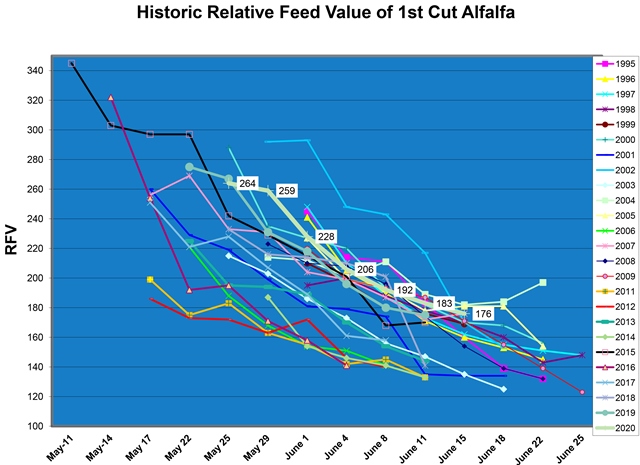

It has been determined from past program years that most alfalfa fields reach the optimum 150 RFV (Relative Feed Value) stage at early to mid-bud stage, and not at the traditional late-bud/first-bloom stage. Results showed that RFV dropped an average of five points per day in each program year (1995-2009), with the decline in RFV most rapid in the early part of the spring. For producers targeting a forage quality of 150 RFV in the yard, we recommend cutting the alfalfa when it’s reached 170 RFV, as quality will drop an average of 20 points between cutting and delivery in the yard.

This year, the Green Gold program will use two separate methods of evaluating standing alfalfa for RFV. The first method is the lab evaluation of scissors clipped forages through the NIR (Near Infrared Spectroscopy) method available at most commercial laboratories. The second method used is the PEAQ method.

PEAQ stands for Predictive Equation for Alfalfa Quality and was first developed at the USDA Dairy Research Facility in Wisconsin. This method has been used to compare with NIR data in previous year’s Green Gold programs and has been shown to be a good indicator of RFV of the standing crop for Manitoba. The PEAQ method is only applicable to the first harvest of the year. No equations have been developed for subsequent harvests; however, generally speaking each subsequent harvest should reach the optimum harvest stage within 500 Growing Degree Days.

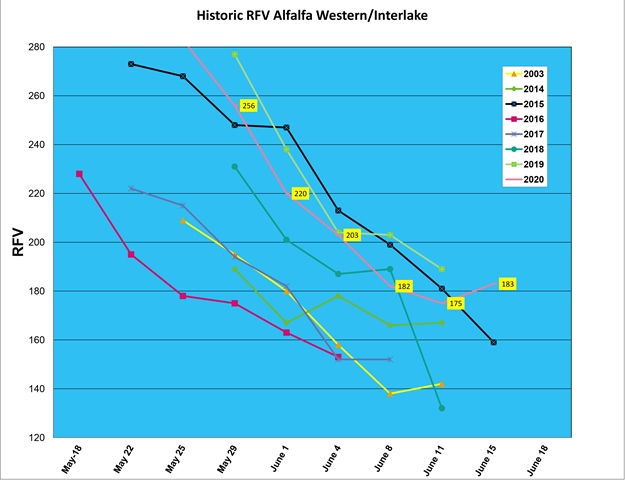

The chart below shows the average Relative Feed Value of alfalfa samples harvested from the Western and Interlake areas of Manitoba between 2014 and 2020. It is important to monitor your alfalfa regularly to ensure it is harvested at the optimum stage. For example, the study showed the range of dates in which an alfalfa crop will reach optimum harvest date (170 RFV) is approximately 3 weeks (May 31 to June 13), with the average being June 7. This changes from year to year (as per the chart below), so do not depend upon a calendar date, but monitor regularly throughout the season and each year.

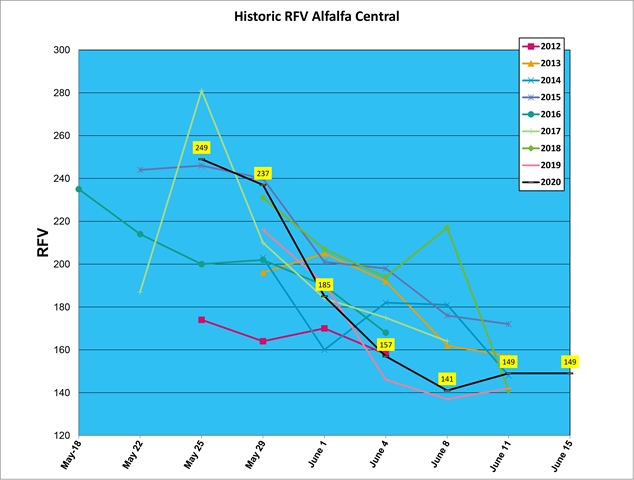

The chart below shows the average Relative Feed Value of alfalfa samples harvested from the Central region of Manitoba between 2012 and 2020.

The chart below shows the average Relative Feed Value of alfalfa samples harvested from the Eastern regions of Manitoba between 1995 and 2020.

Data courtesy of the Manitoba Forage and Grassland Association Green Gold Program webpage.

It should be noted that results will vary from region to region, generally later within 1-2 weeks later in the western and northern regions of Manitoba. The chart below shows the average Relative Feed Value of alfalfa in Manitoba on June 11, the average target harvesting date for Steinbach.

Using Green Gold Information in Deciding When to Cut

Please note that there are several adjustments that need to be made in order to cut based on Green Gold information:

- Expect about 15 to 20 points RFV loss between the standing crop and the harvested crop, due to leaf loss and continued respiration.

- If the sample turn-around time is one day, the hay will be five points lower than when cut.

- The percentage of grass in the stand will also lower the RFV of the hay.

- Alfalfa grown on lighter soils is usually more advanced that alfalfa grown on clay soils.

- Unless you have the capacity to harvest all your hay in one day, start your harvest early to produce the highest quality forage.

Forage quality needs of cattle expressed in Relative Feed Value (RFV)

Using Relative Feed Value (RFV) to Rate Quality

In recent years, the use of Relative Feed Value (RFV) has become a common industry standard of expressing forage quality.

RFV is a calculated figure based on lab analysis for the amount of two types of fibre in the plant – the undigestible portion known as acid detergent fibre (ADF), and the digestible portion known as neutral detergent fibre (NDF). These provide an indication of potential daily forage dry matter intake.

RFV is a reliable method of comparing the feed value of different forages, and many livestock producers use it to sort their feed supply according to the needs of their different livestock requirements (see diagram below).

Grasses Influence RFV

Most grasses are higher in fibre compared to alfalfa (see diagram below), and therefore reach RFV of 150 more quickly than alfalfa. If you want the same quality forage (RFV) with an alfalfa-grass mixture versus pure alfalfa, you need to start harvesting one week earlier, as the following table indicates. The next table gives you the RFV variation among different grass species at the same stage of maturity.

Influence of Cutting Date on RFV:

| Cutting Date | Alfalfa | Alfalfa/Brome | Alfalfa/Timothy |

| Week 1 | 275 | 217 | 230 |

| Week 2 | 204 | 162 | 178 |

| Week 3 | 164 | 138 | 178 |

| Week 4 | 130 | 113 | 121 |

| Week 5 | 116 | 105 | 101 |

Reference: Spandi and Hesterman: Michigan State University

RFV of Grass-Alfalfa Mixtures -- Same Maturity:

| Mixture | Protein % | ADF % | NDF % | RFV |

| Alfalfa | 19.8 | 35.2 | 40.7 | 140 |

| Alfalfa/Brome | 17 | 37.7 | 46.8 | 118 |

| Alf/Orchard | 16.8 | 39.5 | 49 | 110 |

| Alf/Timothy | 18.1 | 39 | 46.9 | 116 |

| Alf/Reed Canary | 18.8 | 39.4 | 46.3 | 117 |

| Alf/Tall Fesuce | 16.6 | 40.4 | 52.1 | 102 |

Reference: Jim Johnston, New Liskard 1995

Fibre Composition: Alfalfa vs. orchardgrass

Relative Forage Quality:

Some soft grasses, such as Orchard Grass can have higher levels digestibility, therefore are often undervalued in a traditional RFV test. For these reason a new test called Relative Forage Quality (RFQ) was developed at the USDA Dairy Research Facility in Wisconsin. Relative Forage Quality measures both the amount of fibre in the plant, and the actual digestibility of that forage using rumen fluid in the lab.

See this page for more information on RFQ

The Drying Process

Knowing when the field is ready to harvest is one thing, but it is quite another to harvest high-quality hay in spite of untimely rains. The following diagram will help you understand the drying process, and help you make critical management decisions in order to produce high-quality forage.

Electronic moisture testers or the microwave test are valuble tools for determining forage moisture levels. Contact Manitoba Agriculture and Resource Development for information on how to determine forage moisture content.

Tips for Producing High-Quality Hay

- Cut early in the morning to obtain maximum drying time in one day. Dry to less than 50% moisture as quickly as possible to reduce transpiration losses.

- Cut only the amount of forage that can be baled in one day.

- Increase the drying rate by laying forage out in a wide swath, drying to below 50% moisture, and then turning.

- Raking, "tedding" or "fluffing" the swath, or double conditioning it (using mower with conditioner, minus cutter bar) is too aggressive for legume hays, but will work for grass hays.

- Use a swath turner early in the morning before baling to gently flip the swath, so lower portions will dry.

- Reduce leaf loss by raking or turning swath only when forage moisture content is at or above 40%, in order to reduce leaf loss.

- Reduce leaf loss by raking alfalfa when the relative humidity of the air is about 50 per cent -- such as in an early-morning dew.

- Consider a wider, flatter swath as opposed to a taller, narrower one. In average conditions, a wider swath can be raked in five to nine hours after cutting, at about 40% moisture. On the other hand, even though it might dry faster, a wider swath can be more affected by bleaching, dew and rain than a narrower one. As well, a narrower swath is easier to flip, and it allows more wind to blow through.

- Cut high enough to avoid foreign material (pocket gopher and mole hills, etc.).

- Consider using several balers to achieve a more-uniform quality hay lot with less leaf loss and sun bleaching.

- Monitor bale moisture levels hourly in the field. Although safe moisture levels for baling vary with the size and density of the package, levels should be below 18% (preferably 15%). Note that for export, forage in containers must not exceed 12% moisture.

- Store all harvested hay (square and round bales) under cover immediately. Hay sheds are the most economical form of storage in the long term, although you might consider tarps as economical alternatives.